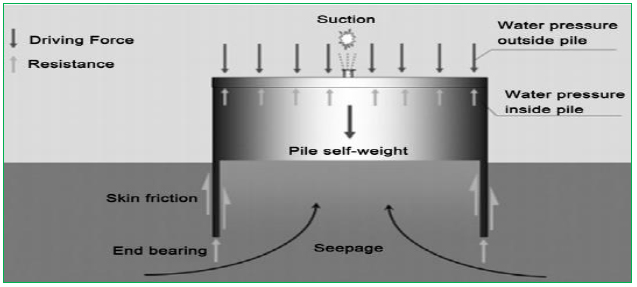

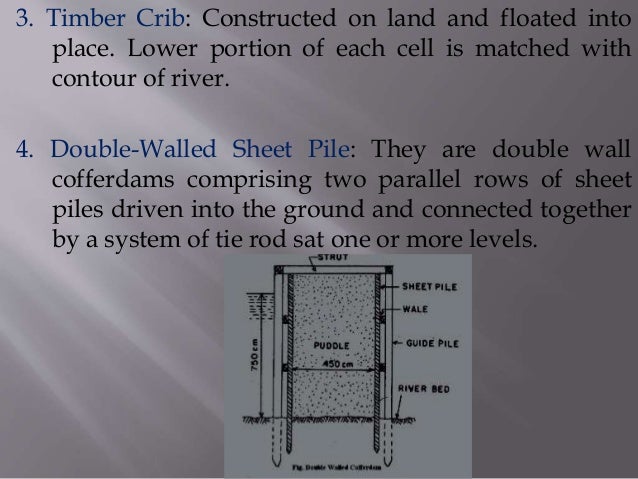

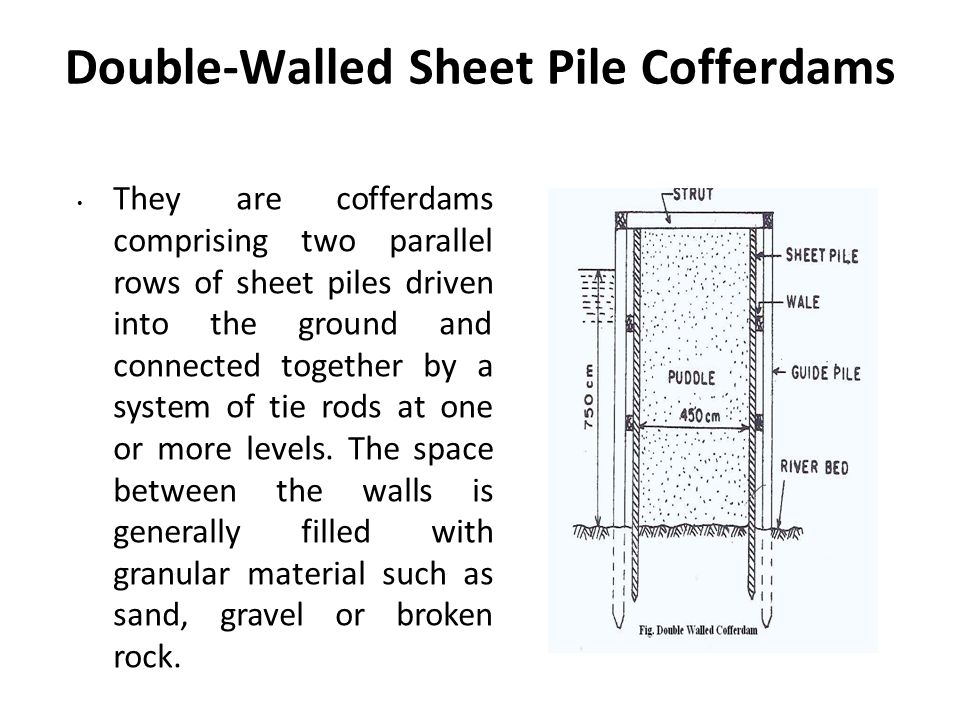

They are cofferdams comprising two parallel rows of sheet piles driven into the ground and connected together by a system of tie rods at one or more levels.

Double sheet pile wall cofferdam design.

The design have been done using both an analytical calculation and a numerical model using plaxis 2d.

Sometimes an inside berm provides to take the phreatic line.

Sometimes an inside berm is provided to keep the pheratic surface within the berm.

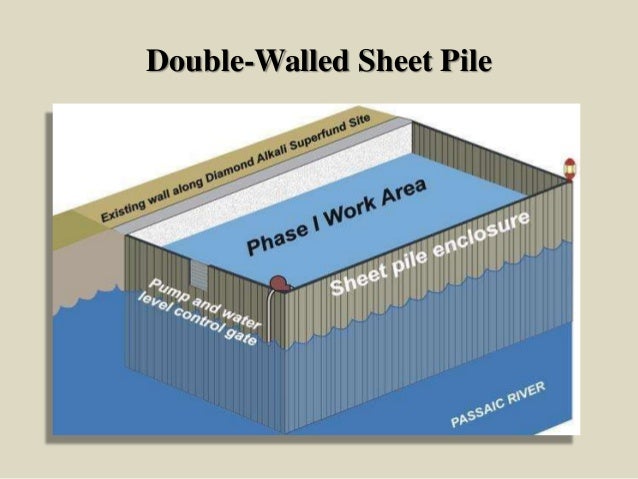

Double walled sheet pile cofferdams.

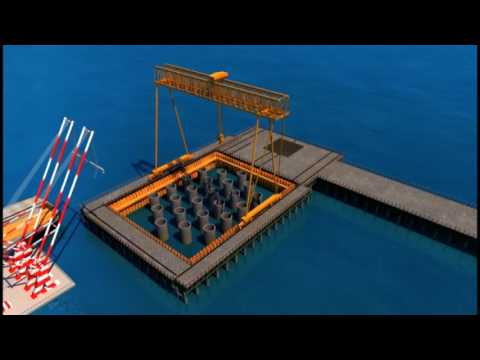

The double wall sheet pile cofferdam in aarhus habour is designed the cofferdam is part of the construction pit for the new media house in aarhus.

Used sheeting must be in good conditions.

The walls of the temporary structure should be practically water tight or at least they should be able to exclude water to such an.

Where h is height of water.

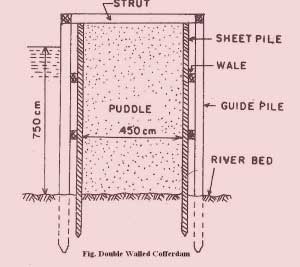

The width between the parallel piles is h 2 1 50 m.

This consists of two straight parallel vertical wall of sheet piling tied to each other and the space between them filled with soil.

Double wall sheet pile cofferdam higher than 2 5 m should be strutted.

Its installed on the seabed of the existing basin which consist of mainly soft clay.

A double wall sheet piling cofferdam comprises two straight parallel vertical walls of sheet piling tied to each other.

The space between the walls is generally filled with granular material such as sand gravel or broken rock.

They are double wall cofferdams comprising two parallel rows of sheet piles driven into the ground and connected together by a system of tie rods at one or more levels.

Cofferdam types of cofferdam.

This type of cofferdams if higher than 2 5 m should be strutted.

If the area to be excavated is relatively small in area or the wall to wall distance is reasonable internal cross bracing consist ing of wales and struts is practical.

Sheet pile cofferdams are constructed on land for any under ground construction where workmen and adjacent structures must be protected against collapse of the excavation walls.

The space between the walls is generally filled with granular material such as sand gravel or broken rock.

Subsection 704 steel sheet piling and cofferdams provide new or used continuous interlocking steel sheet piling including connections in corner pieces.

Provide minimum nominal section modulus of at least 18 1 cubic inches per foot of wall when installed next to traffic or supporting traffic.

The gap between walls is filled with soil.

197 double walled cofferdams are those in which two parallel rows of steel sheet piles are connected with means of a track or a plurality of steel enclosed purlin brackets.

Double walled sheet pile.

The width between the parallel piles is empirically set as h 2 1 5m.

A sketch of double wall cofferdam is given in fig 4.

Design method of double row wall steel sheet pile cofferdam views.

Double wall sheet piling coffer dams higher than 2 5m should be.